NEWS

True fully synthetic motor oil (Category 5 ester base oil) - first used in the latest aviation turbojet engines

Date  2023.06.05

2023.06.05

Ester oil is a kind of high-end synthetic lubricating oil that is very popular now. It was developed by the Germans during World War II to solve the problem of starting tanks and locomotives in the cold zone. Later, it was widely used in aviation and other fields. Gradually switch to motor sports. Ester base oils are formed by catalytic dehydration of organic acids and alcohols. Commonly used are diester, polyol ester and compound ester.

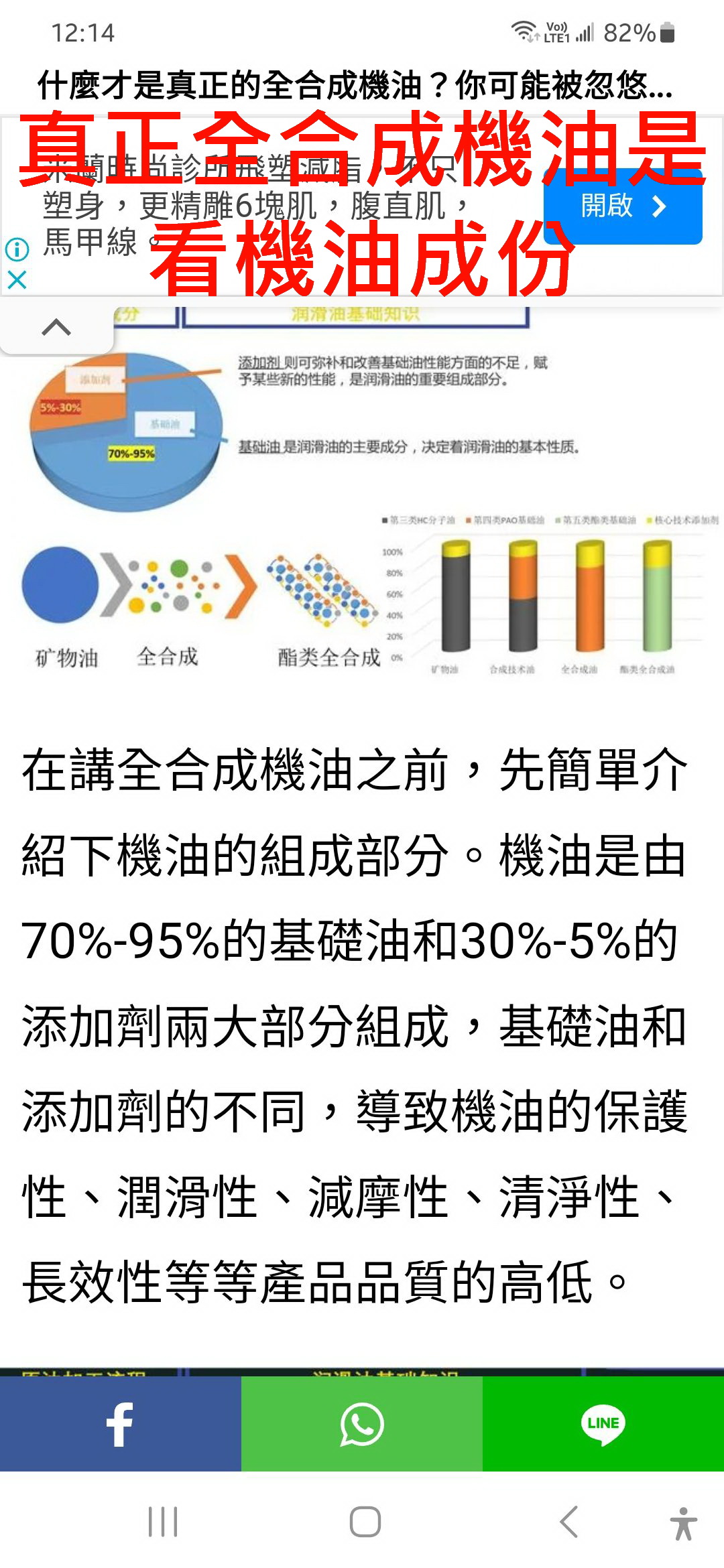

Ester products contain various forms of oxygen atoms such as carbonyl oxygen and alcohol oxygen, which are functional groups that distinguish ester synthetic oils from general mineral oils, and are polar. The base oils of the three types of

synthetic oils and PAO synthetic oils do not contain such groups. In the lubrication process, the ability to form a thick oil film between the friction pairs is critical to the lubrication effect, and compounds containing polar groups are more likely to be adsorbed on the friction interface to form an effective tough oil film. The same function, non-polar synthetic oil is achieved by adding additives. From the product description, you can see words such as diester, alcohol ester, etc. In fact, the synthesis raw materials are different, and the reaction mechanism is similar.

Ester fully synthetic motor oil, where is it stronger?

Everything has two sides, and ester oils are no exception. Let’s talk about the advantages first:

Advantages of Ester Synthetic Motor Oils

1. Good thermal stability. From the perspective of thermal decomposition temperature, diester oils are generally around 280 degrees, and alcohol esters are more than 300 degrees. This is related to its molecular structure. The fully hindered ester esterified with neopentyl polyol has a higher decomposition temperature.

2. The polar structure gives this kind of oil special lubricating performance, and it is easy to adsorb on the interface to form a stable oil film. Even if it is cold, it will not return completely, providing good low temperature protection. For example, compared with mineral oil lubricating oil, the polar functional group of ester group is sucked on the friction pair interface like the sucker of gecko, and it is not easy to

fall off even under the condition of low temperature and cold car.

3. Strong sensitivity to additives. It can be well integrated and synergistic with additives such as antioxidant and anti-wear.

Disadvantages of synthetic ester oil

The biggest disadvantage of ester oils is their hydrolytic stability and material compatibility. Because of the polar group, ester oil is easy to absorb moisture (remember to tighten the cap when you use the rest). The stability of polyester to pure water is not bad, and it is unstable in acid and alkali environment. Since the engine oil contains many additives containing phosphorus and sulfur, and there will be fine metal particles worn down during the working process, the additives will produce acidic substances under the metal catalysis, which further catalyzes the hydrolysis of the ester. Ester will obviously swell rubber products of certain structures, which is also one of its disadvantages. However, these disadvantages are alleviated by appropriate modifying additives.

What is the difference between ester synthetic oils?

Ester synthetic oil contains various forms of oxygen atoms such as carbonyl oxygen and alcohol oxygen, which makes ester synthetic oil different from the functional group of general mineral oil and has polarity; while the base oils of three types of synthetic oil and PAO synthetic oil are not Contains this group, which is the biggest difference between lipid synthetic

oil and ordinary synthetic oil. Active adsorption oil film and passive adhesion oil film During the lubrication process, the formation of a thick oil film between the friction points of the lubricating oil is critical to the lubrication effect. Compounds containing polar groups are more likely to be adsorbed on the friction interface to form an effective tough oil film. The same function, non-polar synthetic oil is achieved by adding additives. Mainly rely on a certain viscosity to adhere to the friction interface. When the engine stops working, this adhesion gradually flows back and falls off under the action of gravity, and the oil film becomes very fragile. The oil film produced by chemipolar adsorption can be maintained for a long time after the engine is stopped, providing uninterrupted lubrication for the engine.

https://www.bharatpetroleum.in/blog/Blog-Detail.aspx?id=22 SYNTHETIC OILS - FINDING THE REAL ONE

PICTURES

VIDEOS