NEWS

Latest aviation jet turbine engine lubricating oil in the world-Advantages and Applications of Neopentyl Polyol Ester

Date  2024.08.02

2024.08.02

For decades, DLE has tirelessly emphasized the importance of base oils in motor oil formulations, especially highlighting the base oils used in the latest aviation jet turbine engines.

Only by using the highest quality base oils can you ensure that your car's engine runs without worries.

No standard commercial motor oil can replace the superior aviation-grade polyol ester base oils.

This commitment has helped a small German oil company rise to become one of Germany's most renowned oil producers.

Over the past 10 years, it has won the GT3 24-hour endurance race four times, relying on its own laboratory to develop polyol ester racing oils, and later, neopentyl polyol ester racing oils.

These oils are supplied to its own GT3 racing team, which participates in various competitions, continuously improving the quality and technical development of its branded motor oils.

In today's automotive industry, where sales drive everything, even data and certifications can be fabricated.

The true measure of quality lies in the motor oil itself—it's the genuine article.

What is Mobil Jet Oil?

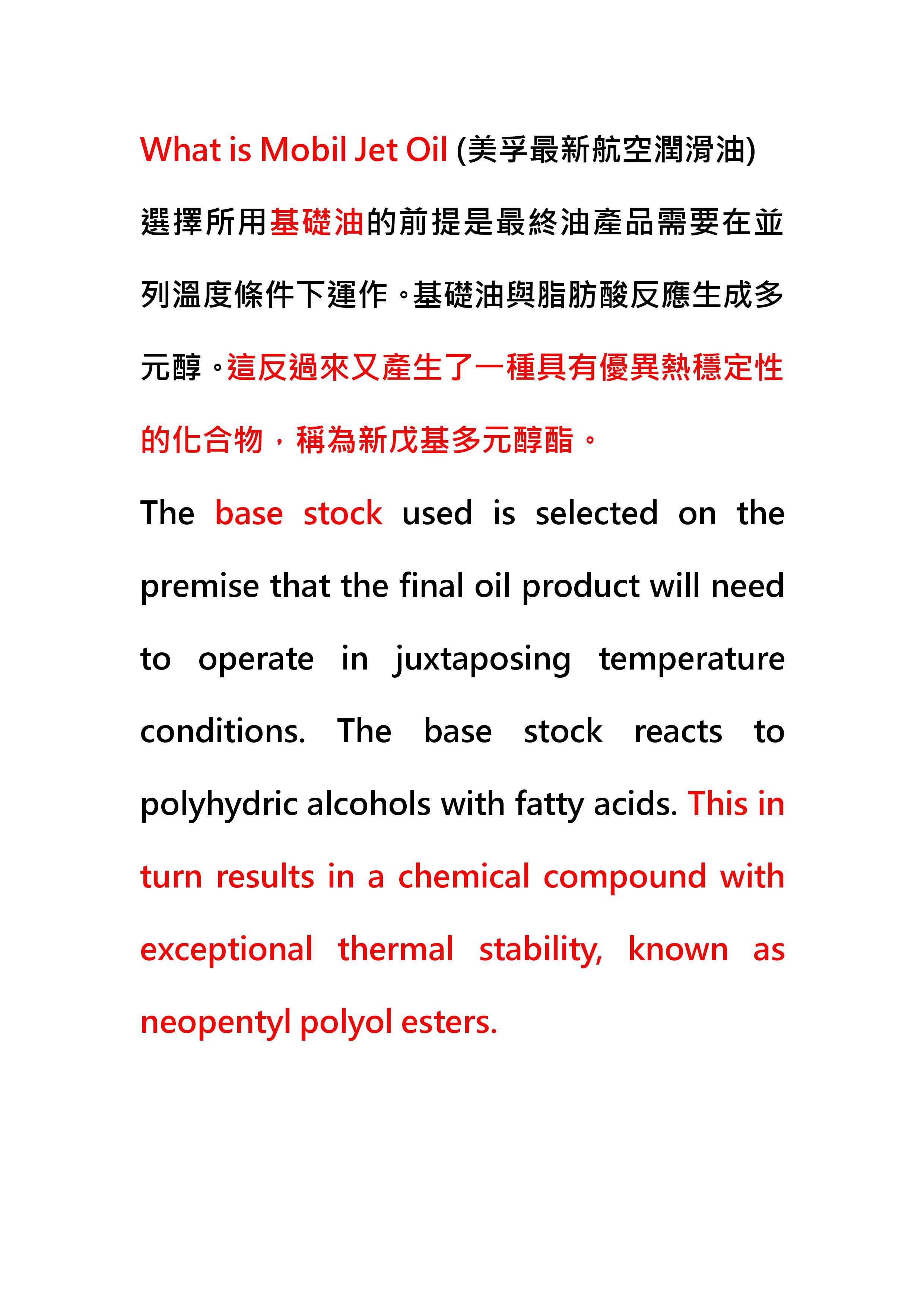

Mobil Jet Oil is a class leading lubricant for aircraft, available in three distinct product offerings with unmistakable livery; consisting of Mobil Jet Oil II, Mobil Jet Oil 387 and Mobil Jet Oil 254. Comprising of the highest quality base stock and additive formulation, Mobil Jet Oils withstand extreme temperatures that can vary from - 40°C to 250°C: the conditions experienced in aviation and aerospace industries as a matter of routine.

This synthetic lubricant manufactured by ExxonMobil meets and exceeds the requirements that standard petroleum-based oils are not capable of. It is in part due to the complicated science of developing Mobil Jet Oil that it can take between seven and fifteen years from creation to full approval and commercialisation. Not only is it time consuming, but having the Mobil Jet Oils approved to military and AE AS5780 specifications is both difficult and costly, something that demonstrates the desire to provide MRO customers with the most efficient, high quality jet oils on the market.

The base stock used is selected on the premise that the final oil product will need to operate in juxtaposing temperature conditions. The base stock reacts to polyhydric alcohols with fatty acids. This in turn results in a chemical compound with exceptional thermal stability, known as neopentyl polyol esters.

Arguably, the most important substances in the additive package are antioxidants. In a sacrificial way, the antioxidants degrade while protecting the base stock and prevents the jet oil form forming harmful deposits. This can be the cause of discolouration often noted with jet oils in service.

So how do Moove Aviation know that Mobil Jet Oil is one of the best products out there?

As a distributor, we are unique in the fact that we exclusively specialise in ExxonMobil aviation products, resulting in unequalled quality control and customer service

ExxonMobil manufacture both high-quality, class-leading base stocks & additives, packaging the final product under controlled environments

After testing, a certificate of quality is issued by ExxonMobil for each batch of jet oil produced.

Moove Aviation is at the forefront of distributing the finest aviation lubricants available from ExxonMobil; who spend years developing and improving top of the range jet oils that surpass the expectations our customers.

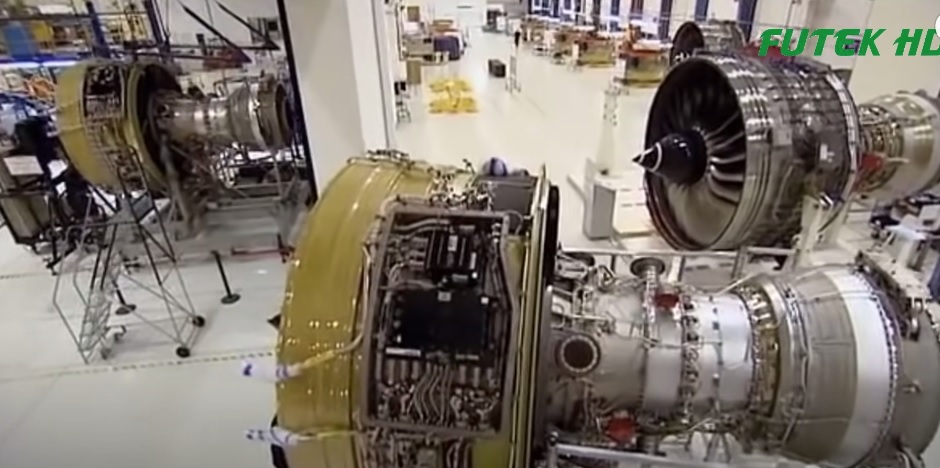

In order to comply with such extreme requirements, aviation turbine oils use very carefully selected and manufactured high performance components. They are typically composed of high quality polyol ester base fluid (93 to 95%), and anti-oxidant, anti-wear and corrosion inhibiting additives (5 to 7%). Earlier generation jet engine oils, especially for military engines, were based on diesters, i.e. esters of diacids. Diesters of sebacic acids, in particular, have been used as base fluids for the MIL-PRF-7808 Grade 3 turbine oils. However, diesters break down through the ß-elimination mechanism to olefins and acids, because of the presence of a hydrogen atom on their alcohol chain, in the beta position.

Neopolyol esters do not have any ß-hydrogen in their molecules, so they decompose at a much higher temperature (320 to 340°C), while diesters decompose at about 280°C. Due to their poorer thermal stability, diesters have been dropped and replaced by neopolyol esters. Neopolyol esters are the only base fluids that deliver the thermal and oxidative stability, lubricity, cleanliness and low temperature behavior required for jet engine lubrication.

Reference articles from Mobil and NYCO

PICTURES

VIDEOS