NEWS

How to Choose the Right Base Oil and Viscosity

Date  2024.10.07

2024.10.07

How to Choose Genuine Fully Synthetic Motor Oil

Motor oil composition (base oil + additives) and long-term misguidance from car manufacturers regarding oil viscosity often mislead car owners.

When selecting motor oil, car owners are frequently told by manufacturers that using non-OEM oil will void the warranty.

This forces many owners to use the OEM's thinner oil, which has led to numerous reports of engine issues shortly after use.

Most of these problems are related to the motor oil being used.

Choosing high-quality motor oil is essential.

"Good oil means good viscosity."

However, I consulted a German oil company about whether motor oil quality is directly related to viscosity, and they responded that there is no direct connection.

The quality of motor oil depends on the quality of the base oil and additives.

Higher viscosity does not necessarily mean better oil.

It's more about the development of polyol ester base oil technology, which improves high-viscosity lubrication performance, often outperforming extremely low-viscosity oils.

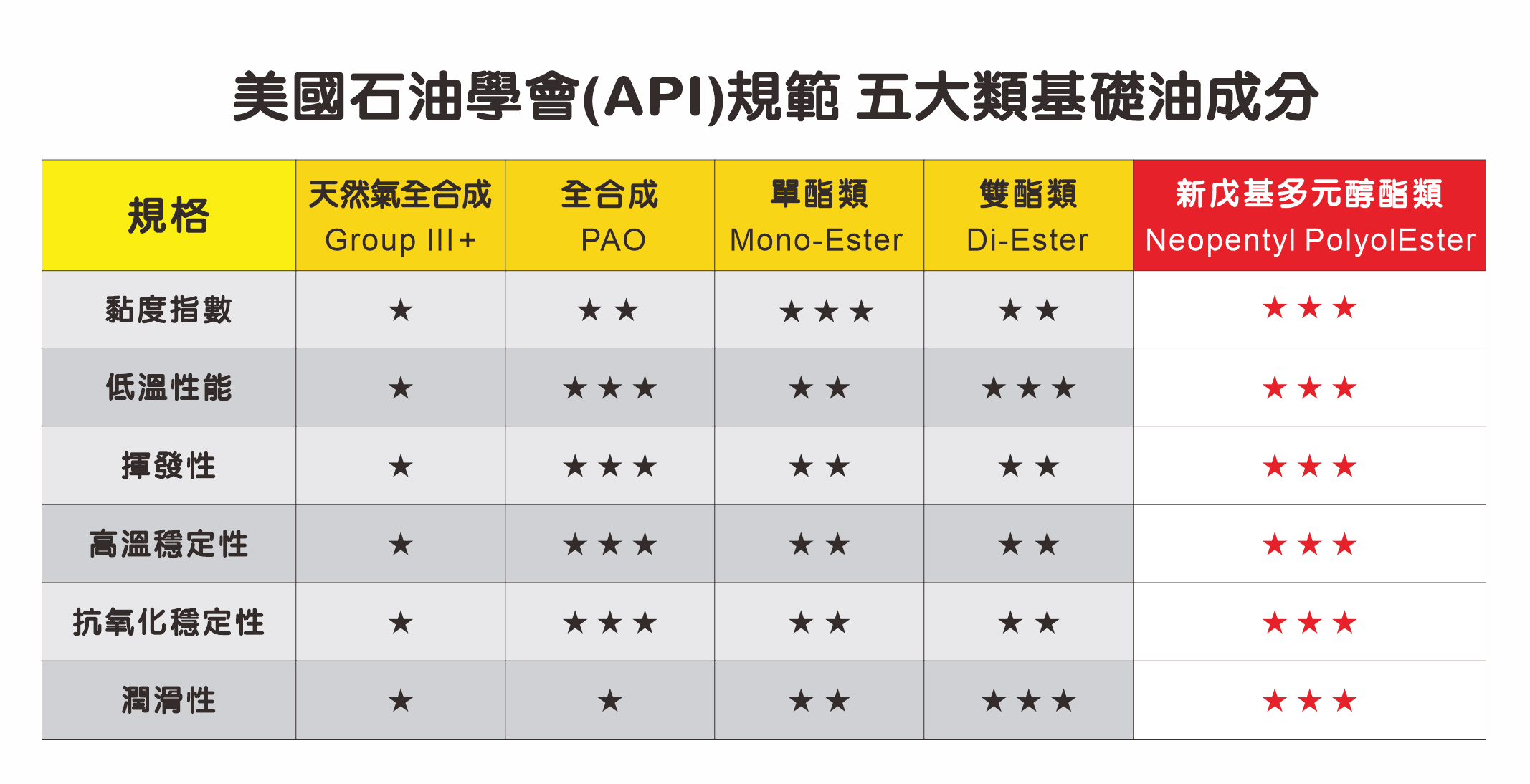

DLE motor oil uses the best aviation-grade base oils: Neopentyl Polyol Esters and Polyalphaolefin (PAO).

These are globally recognized as the best and most advanced oils for aviation and aerospace turbine jet engines.

Neopentyl Polyol Esters are classified as Group V base oils, combined with Group IV base oils.

Neopentyl polyol esters contain no β-hydrogen in their molecular structure, allowing them to decompose at higher temperatures (320 to 340°C), whereas diesters break down around 280°C.

Due to their lower thermal stability, diesters have been phased out and replaced by polyol esters.

Polyol esters are biodegradable, non-toxic, and are considered the most thermally stable synthetic ester base oils, with a thermal decomposition temperature about 50°C higher than that of diesters.

Neopentyl polyol esters offer superior lubrication compared to diesters, mineral oils, and polyalphaolefins (PAO), while also being environmentally friendly, safe, and renewable.

They are commonly used in aviation engine oils, refrigeration oils, and high-temperature chain oils.

Additionally, polyol esters are used in air compressor oils and fire-resistant hydraulic fluids due to their excellent oxidation stability, low carbon deposit formation, and non-flammable properties.

The thermal stability of polyol esters is generally about 50°C higher than that of diesters.

If the hydrogen atoms on the α-carbon of the acid molecule are replaced by alkyl groups, the resulting esters are called fully hindered esters.

Polyol esters are considered non-toxic compounds and are less irritating to the skin than glycerol esters (natural oils).

For more than a decade, DLE has used the most advanced aviation-grade Neopentyl Polyol Ester base oil and has collaborated with German laboratories to develop cutting-edge automotive oils.

These oils have been tested in long-term endurance races such as the 24-hour GT3 races, something that OEM and commercial oils typically do not undergo.

This oil genuinely extends the life of car engines and prevents severe wear of internal engine components.

PICTURES