NEWS

Carefully choose ester oil--Polyol esters, have largely replaced diesters in high-temperature applications .

Date  2012.05.13

2012.05.13

1-ESTER.2-DOUBLE.ESTER.3-POLYOLESTER.

Dibasic Acid Ester (Diester)

The properties of diester are somewhat similar to that of PGs. It has excellent oxidative and thermal stability, very high VI and excellent solubility. This excellent solubility makes it a good choice for reciprocating compressors, where valve deposits can be a huge problem. Another common application for diester is in synthetic engine oil. It is often used as an additive with PAO basestocks to provide the necessary solvency for the engine oil’s large additive package. As a side effect, the synthetic engine oil will have excellent detergency. The negative attributes of diester are the high price and poor hydrolytic stability.

Polyol Ester

Polyol ester basestocks have several excellent performance properties, including thermal stability, super-high VI and fire resistance. Of the base oils mentioned in this column, it is probably the best choice for very high-temperature applications. The two most common applications for polyol ester are fire-resistant hydraulic fluids and jet engine oils. They can be used in engine oils and compressor applications, as well. The negative attributes are the same as those for diester.

Polyol Esters

The term "polyol esters" is short for neopentyl polyol esters which are made by reacting monobasic fatty acids with polyhedric alcohols having a "neopentyl" structure. The unique feature of the neopentyl structure of polyol alcohols molecules is the fact that there are no hydrogens on the beta-carbon. Since this "beta-hydrogen" is the first site of thermal attack on diesters, eliminating this site substantially elevates the thermal stability of polyol esters and allows them to be used at much higher temperatures. In addition, polyol esters usually have more ester groups than the diesters and this added polarity further reduces volatility and enhances the lubricity characteristics while retaining all the other desirable properties inherent with diesters. This makes polyol esters ideally suited for the higher temperature applications where the performance of diesters and PAOs begin to fade. Polyol esters can extend the high temperature operating range of a lubricant by as much as 50 - 100 C due to their superior stability and low volatility. They are also renowned for their film strength and increased lubricity which is useful in reducing energy consumption in many applications. The major application for polyol esters is jet engine lubricants where they have been used exclusively for more than 30 years. In this application, the oil is expected to flow at -54 C, pump readily at -40 C, and withstand sump temperature approaching 200 C with drain intervals measured in years. Only polyol esters have been found to satisfy this demanding application

Polyol esters, or Neopentyl poly esters, have largely replaced diesters in high-temperature applications where oxidative stability is critical. Common applications include their use as lubricants in aircraft engines, high-temperature gas turbines, hydraulic fluids, and as heat exchange fluids. They can also be used as a co-blended basestock with PAOs to enhance additive solubility and reduce the tendency of PAOs to shrink and harden elastomers.

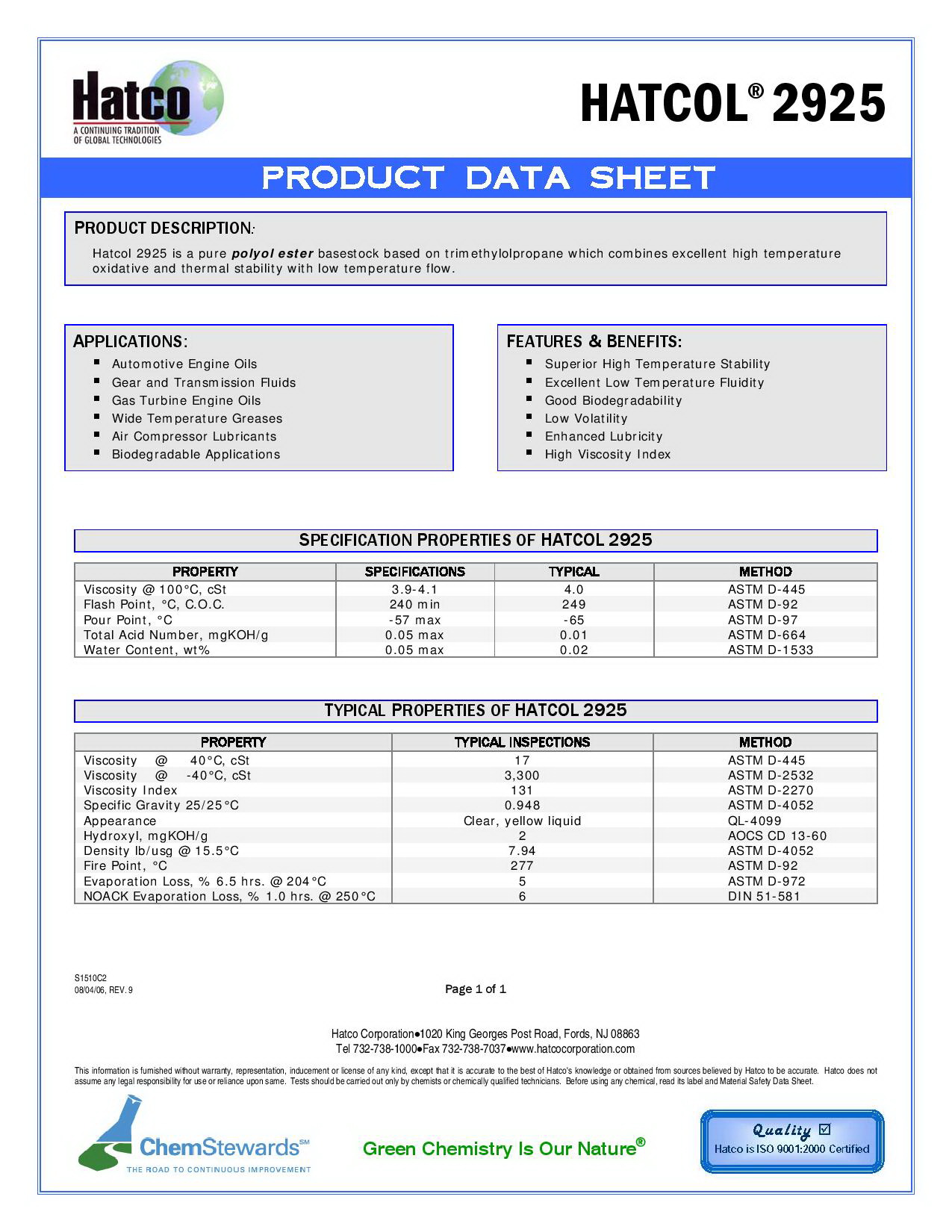

(POLYOLESTER-BASE):FEATURES&BENEFITS:

Superior high temperature stability

Excellent low temperature fluidity

Good biodegradability

Low volatility

Enhanced lubricity

High viscosity index

(DOUBLE-ESTER BASE): FEATURES&BENEFITS:

Very good high temperature stability

Excellent low temperature fluidity

High viscosity index

Good biodegradability

Low volatility

High lubricity

PICTURES